working principle:

working principle:

The air passes through the filter and the heater, enters the air distributor at the top of the drying tower, and then enters the drying chamber evenly into the chamber. The material from the material and hot air in parallel contact, the rapid evaporation of water, in a very short period of time for the finished product. The finished product is discharged from the bottom of the drying tower and the cyclone separator, and the exhaust gas is discharged by the fan.

Features:

● Drying speed is fast. After centrifugal spray, the surface area is greatly increased. In the high temperature air stream, 95-98% moisture can be evaporated instantaneously, and the drying time is only a few seconds.

● The use of co-current spray-dry form can make the droplets and hot air flow in the same direction, although the hot air temperature is high, but the hot air into the drying room immediately contact with the spray droplets, indoor temperature drop, and the material wet bulb temperature basic It is also suitable for heat-sensitive materials to dry.

● Because the drying process is completed in an instant, the finished product particles are able to keep the droplets in a similar spherical shape, and the product has good dispersibility, fluidity and solubility.

● The production process is simplified and the operation is easy to control. Spray drying is usually used for solutions with a solid content of less than 60%. After drying, no further pulverization and screening are required, which reduces the production process and simplifies the production process. For the product size, bulk density, moisture, in a certain range, can change the operating conditions to adjust.

● easy to operate, high degree of automation, easy maintenance.

Applications:

Spray Drying Machine is mainly used in chemical industry, metallurgy, electronics, ceramics, mining, pesticide. Dyes, pigments, detergents, pharmaceutical intermediates, flue gas desulfurization, wastewater treatment and other industries in a variety of emulsions, suspensions, pastes and aqueous solutions such as liquid material drying.

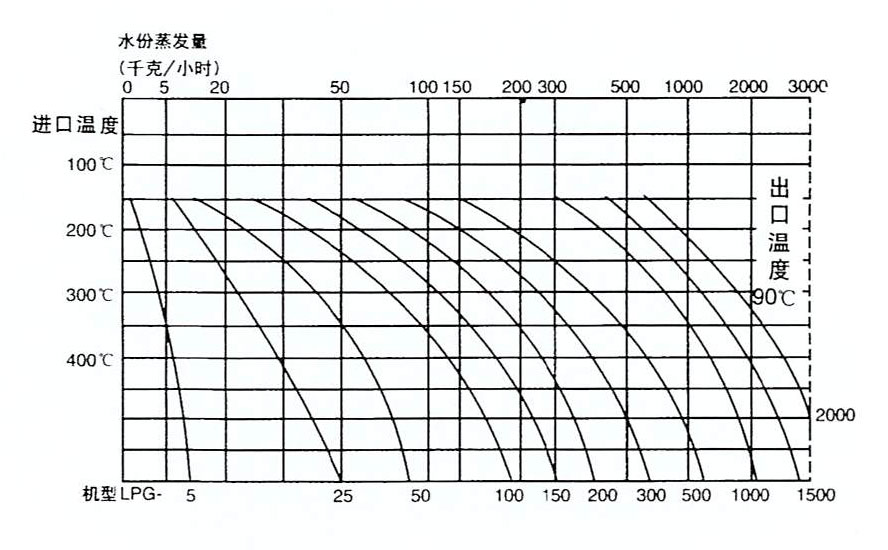

Water evaporation curve:

Technological process:

.jpg)

| Project / model | High - speed centrifugal spray | ||||||||||||||||

| 5 | 25 | 50 | 100 | 150 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | |

| Maximum water evaporation (kg / h) | 5 | 25 | 50 | 100 | 150 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 |

| Spray form | High speed centrifugal nebulizer | ||||||||||||||||

| Atomizer speed (r / min) | 25000 | 18000 | 15000 | 12700 | 11800 | ||||||||||||

| Spray disc diameter (mm) | 60 | 120 | 150 | 150 | 180 | 210 | |||||||||||

| Heat source (optional) | Fuel, natural gas, gas, coal, steam, electricity and so on | ||||||||||||||||

| Note: The amount of water evaporation and material properties, including heat and hot air import and export temperature | |||||||||||||||||